Case Studies

Case Studies

In 2018, Airway completed a comprehensive new build installation project for Ben Burgess in Ellington Cambridgeshire. The project involved a range of mechanical and HVAC systems (You can read about this project below).

In 2023 Ben Burgess required a new build installation in Oakham, Leicestershire. A new project designer (K Garnham Designs) and consultant (Create Consultants) was instructed to manage the project via Ben Burgess and due to the quality of the work in Cambridgeshire they enlisted Airway again.

Tasked with installing VRF Air Conditioning & Heating Systems and AHU Fresh Air Ventilation – Airway successfully installed two Mitsubishi PURY-EM R32 Air to Water VRF Systems, including 4 Internal Branch Control Boxes and 29 Cassette Fan Coil Units. Additionally, a DX Split System for the IT Server Room, a Mitsubishi Touch Screen Controller, and a Mitsubishi Refrigeration Leak Detection System were integrated. The ventilation system comprised a VES AHU MAX/D/SP/S with Plate Heat Exchanger and Electric Pre Heat Battery, complete with associated ducting, fixings, dampers, and supply and extract grilles.

Airway was later asked to also handle all mechanical works. The scope expanded to cover in-coming gas and water mains, direct gas heating with Dunham Bush Heaters, hot water boilers, pressurization systems, water pumps, water softeners, LTHW flow and return pipework, and LTHW radiators in common areas.

During installation, Airway identified missed and over-specified elements that the previous mechanical company had made. They took the initiative to re-specify a Full M&E Control Panel, revise duty run and stand-by LTHW pump sets and implement new diverter valve sets.

Airway ensured all systems were fully commissioned, including gas certification, water treatment certification, FGas testing, and air flow balancing. The entire process was overseen by Airway’s install teams, showcasing their commitment to delivering a fully operational and compliant system. With the project completed ahead of schedule allowing for a seamless transition for Ben Burgess to occupy the building.

Transforming Suffolk Council’s Chambers Air Handling System.

Airway was contracted as a specialist sub-contractor by Dalkia, a part of the EDF group, to enhance the air handling system at Suffolk Council’s Chambers.

The existing system consisted of two separate AHUs and a rudimentary recirculation setup, providing heating through low-pressure hot water coils and cooling using outdated DX units.

In 2022 phase one commenced. Working in tangent with Suffolk County Council design team Concertus a new VES Heat Recovery AHU system was delivered to site in Ipswich. The old plant was all safely de-commissioned by our trained engineers ready to be crane lifted off the roof.

Airway and Dalkia coordinated with Ipswich Town Football Club to utilize their car park facilities for crane operations to remove the old equipment from the roof and install the new system. This occurred on a Saturday morning, involving the placement of a VES MAXI31 heat recovery AHU, two Mitsubishi R32 Heat Pump Condensers PUZ-ZM200, and the Mitsubishi PAC-I control interface.

Our team piped up the refrigeration system and control cables as well as modification and extension of some large 800x650mm rectangular ducting from the new AHU into the roof pods and connected onto the existing ductwork following into the Council Chamber. All the ducting was fully insulated with a weatherproof outer covering also installed.

During this period, Suffolk County Council and their designers at Concertus decided to make several specification changes. Airway engaged the VES site team to transition from a single-stage Heating/Cooling coil to a two-stage model. Additionally, adjustments were made to the control strategy based on the client’s preferences, and VES returned to integrate the system with the site’s Building Management System.

After all these changes the system was commissioned, and airflows read to prove the 1.47m3/sec on both supply air and return and in time for winter season at the end of September 2022.

The existing method of getting air into the chamber was via a number of floor grilles where supply air was pumped into a floor void and allowed to try and reach each floor grille with no means of volume control. Return air was via a Bell Mouth Return above a plasterboard ceiling where small open vents were cut into the ceiling to allow rising hot air into the void. This approach proved inadequate, necessitating the exploration of an alternative solution.

Collaboratively, Airway, Dalkia, and Concertus developed a new internal ducting plan. This plan included cutting back the supply air ductwork where it dropped into the floor void and installing new ducting and 8no. Waterloo Swirl Diffusers into the ceilings. It also required the existing Bell-Mouth Return air ducting to be changed to new ducting and connect also to 8no. Swirl diffusers. This would allow far more controlled airflow on both supply and return air into the chamber.

We successfully completed all our tasks, including comprehensive air flow testing and balancing, two days ahead of the revised schedule. This allowed us to meet the handover date of Monday, September 11th, as planned. The following day, a full Suffolk council meeting proceeded with over 120 delegates in attendance.

Airway Group Installed Mitsubishi Electric Wall Mounted Power Inverter Systems and Walk-in Coldrooms for Royal Papworth Hospital’s Heart and Lung Research Institute.

Royal Papworth Hospital’s new Heart and Lung Research Institute is an exciting development for the hospital, bringing state-of-the-art facilities for research into heart and lung diseases. Airway Group were awarded the contract to install Direct Expansion (DX) Cooling equipment for the IT intake room, SER rooms, and freezer stores on the ground, first, and second floors of the new building.

Energy efficiency was a driving factor in equipment selection, as the project was designed to achieve BREEAM (Building Research Establishment Environmental Assessment Method) certification. BREEAM is a leading sustainability assessment method for buildings and infrastructure projects, used to measure and rate the environmental performance of buildings.

The new Air Conditioning equipment comprised of 14 No.10kw Mitsubishi Electric Wall Mounted Power Inverter systems to serve the IT intake room, SER rooms. Installation included pipework, containment, control cabling, and condensate removal pumps. Each unit also included a ModBus/Bacnet BMS interface to allow for easy and monitoring from the new Building Management System.

In addition, Airway Group installed a further 3 No. 10 Kw Mitsubishi Electric Wall mounted Power Inverter systems to serve the ground Floor MER room. These were configured to provide duty rotation and back-up using Mitsubishi’s own PAR 33 MAA remote controllers.

Mitsubishi Electric PKA-M100KA wall mounted indoor units and PUZ-ZM100VKA outdoor units were used for this project due to their supreme reliability, performance and efficiency. The BMS interfaces used for each of the 17 systems were MelcoBEMS mini’s.

To meet the project’s requirement for two walk-in coldrooms, Airway Group installed these using Scandia GreenFoam panels with an inner ply skin to support shelving, sliding doors with level access, and lighting as per the specification. Each coldroom included a duty and standby refrigeration system controlled by an auto-changeover panel with duty rotation and back-up, as well as trapped person alarms linked to the BMS.

The cold room refrigeration equipment used was from the Searle KEC range of evaporators connected to Danfoss Optyma Plus condensing units.

The installation was completed on time and within budget, meeting the hospital’s requirements for energy efficiency, reliability, and ease of use.

The new systems have helped to ensure great air quality and a high level of temperature control within Royal Papworth Hospital, ensuring a comfortable and safe working environment for staff and patients. Airway Group’s expertise and attention to detail allowed them to provide a tailored solution that met Royal Papworth Hospital’s needs, while also ensuring high-quality workmanship and customer satisfaction.

Overall, Airway Group’s installation of Mitsubishi Electric Wall Mounted Power Inverter Systems and walk-in coldrooms has helped Royal Papworth Hospital to upgrade their facilities, preparing them for the new Heart and Lung Research Institute, and providing a comfortable, safe, and energy-efficient environment for staff and patients alike.

In May 2019, Airway had the task of removing gas boilers from the roof of a building using a crane to make room for new boilers at ARM Ltd, an architecture company based in Cambridge. Our staff worked under strict health and safety procedures to ensure the safety of our own staff and the staff from Intech Environmental, who were working alongside us for the duration of this project.

We removed the old units and correctly disposed of them by recycling the proper materials, whilst our installation team were able to get on with installing the newer models. Our experienced team unpacked, roped up and hoisted the gas boilers onto a crane and carefully manoeuvred them onto the roof of the building.

The team here at Airway were delighted to work on this project, using our decades of experience to complete the job to the highest standard and in a timely manner.

In 2019 our team had the pleasure of working with Ely Archives by installing a brand new air conditioning system and a close control system, giving users complete control over the temperature and humidity of the building. Our work ensured our clients were able to maintain the correct environment to continue to preserve the state of the historic records and other resources related to the history of Cambridgeshire.

The old units were removed and correctly disposed of, with the recyclable material being recycled through the proper channels. The entire installation was completed within three months, all at a competitive rate, so Ely Archives could resume work swiftly. Here at Airway Group, we were immensely proud of the work we completed, as we added a variety of technology to the building, including heat recovery ventilation, circular diffusers, Daikin wall-mounted air conditioners, among many other things.

In March 2018, Airway were tasked with replacing some of the air conditioning units at the University of Cambridge’s Emmanuel College. One of the larger colleges belonging to the University, Emmanuel College caters for around 500 undergraduate students, 150 graduate students, 90 Fellows and 150 members of staff. As such, there are plenty of people inside the college at any given time, and the temperature must be regulated and controlled constantly to keep students, staff and guests alike cool and comfortable.

We removed four old air conditioning condensers from the roof of the college, and replaced them. However, we didn’t install four new units: we installed one singular unit that boasted greater efficiency than the previous four combined. In addition, four commercial chiller units were installed in the basement, fed by insulated pipes which feed them with coolant. These chillers were then connected to the rooftop unit.

The old units were removed and correctly disposed of, with recyclable materials being sent for recycling.

The project was supervised by Matthew, our project manager, and Airway staff were present on site throughout the entire process. The college can now enjoy more efficient, effective air conditioning units!

The team here at Airway Group worked alongside Fleming Construction and a variety of specialists, including designers, consultants and manufacturers, to complete a comprehensive air conditioning system installation over fourteen weeks.

We installed two separate Mitsubishi HRV systems with three hybrid internal boxes and twenty-six internal cassettes covering the entirety of the building. The various control systems were designed to create different environments for a variety of buildings, including showrooms, offices and training rooms. We employ only the highest health and safety standards, especially as our team were working at a height for the majority of the project.

At Airway, we are always thrilled to be working on new and exciting projects like this and enjoy collaborating with other companies to create systems tailored to the businesses exact needs.

Airway were commissioned to remove all existing equipment on the roof at Yamaha, Milton Keynes, so that major roof repairs could take place.

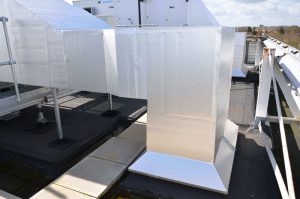

Upon inspection of the equipment, it was evident that the air handling plant was very old, inefficient and unlikely to cope with the stress of the crane lift off the roof. In consultation with the client it was decided that a new bespoke system was needed. A bespoke system was designed and installed to fit the customer’s requirements.

The original installation was extremely compact and poorly set out Airway completely redesigned the installation using a RoofPro plant support and access system. This allowed for efficient use of plant space and good access for future maintenance and service requirements.

The project was completed in multiple phases with the old equipment initially being removed to allow roof works to take place. After roof works were completed the new bespoke AHUs were installed along with a gantry system and platforms to ensure easy future access.

The final phase of the installation was to update the old Hitachi VRF air conditioning system to the latest Daikin VRV IV system. A centralised controller was then installed to allow joint control of both the ventilation and air conditioning.

Get your free no obligation quote